Your budget is often an important factor when evaluating the type of clean room that best meets the needs of your application.

Many times, it is the most important factor.

Portable clean rooms are typically less expensive than their traditional, permanent counterparts. They can also be a cost-effective choice for companies poised to experience growth in the future.

However, the cost of a clean room isn’t simply measured by the dimensions of a space. Here are some of the factors that go into determining a traditional vs. portable clean room cost, from the design phase through installation.

Traditional Clean Room Cost

A traditional clean room, also known as a hardwall clean room, can cost as much as $1,500 per square foot. For a 10’ by 10’ space, this would amount to around $150,000.

A traditional clean room, also known as a hardwall clean room, can cost as much as $1,500 per square foot. For a 10’ by 10’ space, this would amount to around $150,000.

Permanent clean rooms are built into a building and require far more construction considerations than a modular space.

When constructing a building addition, this process often requires multiple contractors, which can take an extensive amount of time to secure. Design and construction permits will be required, as will inspections as the construction of the new space progresses.

Walls and ceilings are built using raw materials. A duct system must be put into place for air flow, especially when a fume hood is required. Plumbing and electrical components must also be designed and installed.

All of these factors add to the design, engineering and construction time of a clean room. The installation of a traditional clean room also takes longer. And, as with any construction project, time equals money.

Portable Clean Room Cost

Portable clean rooms, also known as modular or softwall clean rooms, can cost anywhere from $100 to $150 per square foot. That would put the average cost of a 10’ by 10’ clean room space at $10,000 to $15,000.

This makes portable clean rooms an attractive and economical choice for many businesses that require flexibility, easy construction and a space that has the ability to be altered if future needs change.

While permanent clean rooms can take several months or more to complete, portable rooms can be assembled in days or weeks. Because all the components of a modular clean room have already been manufactured, construction simply consists of assembling the parts together.

Unlike traditional clean rooms where teams of contractors must be hired to build the space, your own staff can assemble a portable room by following a manufacturer’s instructions. Installation services may also be available, depending on the manufacturer.

Because portable clean rooms can be manufactured and delivered quickly, companies benefit from significant cost savings since clean room employees can be up and running much faster.

Other Factors That Contribute To Cost

While portable clean rooms tend to cost less than traditional clean rooms, the price you will pay for either depends on several factors.

Cleanliness Specifications

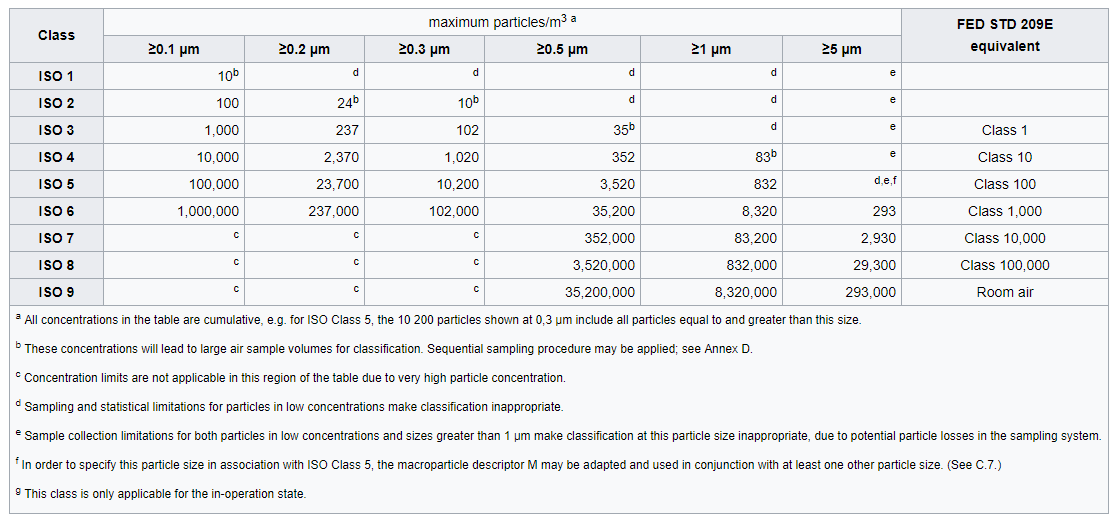

Depending on the clean room classification required for your space, the cost per square foot may vary. The cleanliness of the air inside is measured by the particle quantity and size per volume of air.

Based on this, a room falls into one of nine classifications within the ISO classification system ISO 14644-1. Designations range from ISO 1 to ISO 9, with 1 being the cleanest and 9 considered the least clean.The cleaner the room must be for your application, the more expensive it will be per square foot because more sophisticated equipment will be needed to maintain a stricter standard.

Room Features

The features included in your space will have a significant impact on the final cost of your room as well. Depending on your manufacturing or laboratory requirements, you may need industrial furniture such as workbenches, casework, chairs, cabinets and other pieces.

The materials used in the construction of these furniture pieces also factor into the cost, with materials such as ESD laminate and epoxy resin having a higher price tag because of the materials and the method by which they are constructed.

If a fume hood is needed, the size and power of the hood can influence cost, as well as whether there are any structural improvements needed to support the use of the hood.

Additional Components

Some additional adjustments may be required that could add to the complexity of the clean room installation, which could then impact project costs.

For example, additional considerations could include:

- Whether a floor must be leveled

- If additional outlets are needed

- The temperature in the space and how to rectify any associated problems

- What lighting system is in place

- Whether wall panels or floor-to-ceiling windows are preferred

- The number and size of the windows

- Type of door and how it is secured

Future Plans

A traditional clean room is permanent. This could present a costly problem in the future should your company’s applications change or you experience growth and must move to a new location to accommodate that growth.

A modular design offers a cost-effective solution to companies that anticipate their needs changing in the future. They can change size, configuration or location, either within the same facility or to a completely new location.

This flexibility allows companies to grow without experiencing the painful costs of building a new space with each step forward.

Which Is Better?

There are several factors that impact clean room cost. If budget is a concern, portable clean rooms may offer more financial incentives in both the short- and long-term.

Working with an experienced manufacturer will help you assess which type of clean room is best for your budget, as well as your operational needs now and your operational goals for the future.

Our article, What To Look For When Evaluating Modular Clean Room Manufacturers, helps break down the qualities you should look for when evaluating a top-quality partner.