Solid surface countertops and quartz countertops can have similar appearances, but there are a number of differences between them.

Those differences are important to know when choosing which material is best for your laboratory workspace.

Composition Of Solid Surface Countertops vs. Quartz Countertops

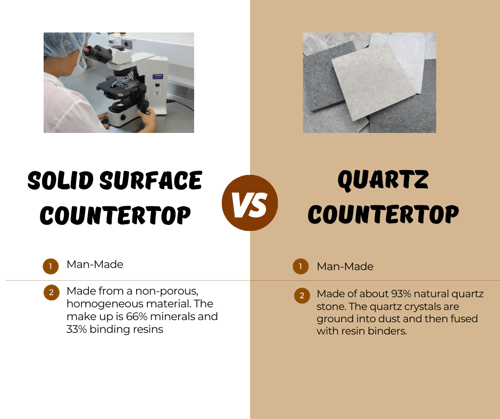

Solid surface countertops and quartz countertops are both man-made. However, when it comes to solid surface vs. quartz countertops, their compositions differ.

Solid surface countertops are made from a non-porous, homogeneous material that maintains the same composition throughout the countertop. Solid surface is similar to plastic in that it is often made from acrylic or polyester resins and features a filler material.

The make-up of solid surface material is around 66% minerals and 33% binding resins. Resin materials can vary from acrylic to polyester and plastic. The mineral portion of the mixture depends on the desired final look and may include minerals like marble and granite. The mineral portion also typically includes aluminum trihydrate, which is a fine white powder that is responsible for the smooth appearance that solid surface counters feature.

This mixture chemically cures and is heated to 140 degrees F or more to form a solid material that can be customized to a specific size and shape.

Quartz countertops are made of about 93% natural quartz stone. The quartz crystals are ground into dust and then fused with resin binders. This process is done under intense heat and pressure, which then forms a solid slab.

Also called “engineered stone countertops,” quartz can be made using a variety of pigments, which allow manufacturers to customize appearances and patterns.

Pros And Cons Of Solid Surface Countertops

Pros

- Moisture resistant: Solid surface is non-porous. This water-proof feature prevents moisture from seeping into tiny cracks or openings on the surface.

- Bacteria, mildew and stain resistant: This non-porous feature allows the countertop material to ward off bacteria and mildew. This means the solid surface is also resistant to stains.

- Invisible seams: From an aesthetic standpoint, solid surface countertops feature invisible seams. Several pieces can be molded to fit perfectly together and used across a large area of countertop space.

- High durability: Because solid surface is homogeneous, this material fares better when impacted compared to multi-layered options like laminate countertops.

- Easy maintenance: Solid surface countertops don’t require extensive care when it comes to cleaning. In fact, they are easy to clean using soap and water or a mild cleaner.

- Easy to repair: When minor damage occurs, it can be easily repaired by sanding the damaged area out with sandpaper or an orbital sander.

- Can be customized: Solid surface countertops can feature a variety of colors and patterns, from vibrant reds and blues to patterns that mimic natural stones.

Cons

- Not resistant to harsh chemicals: Many laboratories regularly use harsh chemicals and cleaners. Solid surface countertops are not resistant to all of these.

- Not heat resistant: Solid surfaces can discolor or crack when they come in contact with heat. For environments that regularly use open flames or other heat sources, solid surfaces may not be the best option.

- Can scratch easily: Although solid surface countertops can withstand some impacts, this material does not fare as well when it comes to scratches. This is because the material is softer than others,such as epoxy resin.

- Aesthetics can suffer: While a major selling point of solid surface countertops is their seamless lines, because this material can scratch easily, its aesthetics can suffer. This is especially true when glossy finishes are used.

- Some repairs require professional care: Although minor repairs can be easily made, any major repairs often require the help of a professional. This includes most repairs to solid surface countertops that have glossy finishes. Repair companies will use sanders and low-speed polishers to create uniform finishes before polishing your countertop to return it back to its high-gloss finish.

Pros And Cons Of Quartz Countertops

Pros

- Moisture resistant: Like solid surface, quartz is non-porous. Again, this water-proof feature prevents moisture from seeping into tiny cracks or openings on the surface.

- Bacteria, mildew and stain resistant: This non-porous feature allows the material to ward off bacteria and mildew. This means quartz countertops are also resistant to stains.

- Heat resistant: Quartz countertops are very heat resistant, although even this feature comes with a limit. Quartz is generally resistant to temperatures up to around 300 degrees F.

- Scratch resistant: Quartz countertops are very hard. On the Mohs hardness scale, quartz scores a 7, whereas diamond (the hardest natural mineral) scores a 10. Quartz countertops are unlikely to scratch or chip because of this hardness.

- Easy maintenance: Quartz countertops don’t require extensive care as well. They do not require special cleaners.

- Can be customized: Because quartz is also man-made the manufacturing process offers buyers the opportunity to choose from a wide range of colors when compared to other natural stone countertops like marble or granite.

Cons

- Not resistant to harsh chemicals or abrasives: Many laboratories regularly use harsh chemicals and abrasives. Quartz countertops are not resistant to many of these chemicals.

- Can only be used indoors: While most laboratories are naturally indoors, there are some situations where a facility may need countertops in an outdoor space, such as outdoor living labs or outdoor science classrooms. The direct sun that can beat down on the quartz countertops will cause them to fade overtime and even warp or split.

- Very heavy: Quartz countertops are very heavy, weighing an average of 16 to 23 pounds per square foot. Solid surface typically weighs just 5 pounds per square foot. Quartz countertops may require professional installation assistance or tools because of their weight.

- Visible seams: Unless the countertop surface area is small, quartz countertops typically feature seams to cover the larger area. That’s because quartz countertops are made in slabs due in part to their heavy weight. While the best manufacturers will make these seams inconspicuous, they are not invisible.

- Some repairs require professional care: Like solid surface countertops, minor chips can be repaired. This is often done using an acrylic adhesive or clear resin, though more major repairs should be done by a professional.

Cost Of Solid Surface Countertops Vs. Quartz Countertops

Cost is an important consideration when weighing whether solid surface countertops or quartz countertops are better for your lab.

better for your lab.

Solid surface countertops cost anywhere between $50 and $200 per square foot. The exact cost depends on a number of factors. These factors include special finishes, edging finishes, pigments and other added features such as whether sinks or backsplashes are made to complement the countertop.

Solid surface countertops can also be customized to resist higher levels of heat found in a laboratory. This material can be heated to around 320 degrees F and cooled in order to improve its heat resistance. This higher level of resistance adds to the product’s durability, but may cost more because of this added feature depending on the manufacturer.

Quartz countertops have a wide price range as well, costing anywhere between $50 and $200 per square foot.

Like solid surface countertops, a number of factors can impact how much your costs will be, from the complexity of the job (such as edging and cutouts) to pigments used and other customizations.

Which Is Best For Your Lab: Solid Surface Vs. Quartz

The ultimate answer of which is better for your lab, solid surface or quartz countertops, lies with your laboratory’s needs and specifications.

Both quartz and solid surface countertops offer stunning looks and high levels of durability thanks to their moisture resistant features. Solid surface countertops provide a seamless look and can be easily molded to fit a sink, backsplash and other custom features. Quartz countertops tend to hold up better to heat and scratches.

It’s possible that neither choice is the best option for your lab, especially if you regularly work with chemicals and harsh abrasives. In this case, you may want to consider other countertop options such as phenolic resin or epoxy resin countertops.

To learn more about your options, our article, Top 5 Materials To Consider For Your Lab Countertops, offers some of the advantages and disadvantages of these alternatives so you choose the best material for your lab’s current and future needs.