Solid surface countertops and laminate countertops both offer their own unique advantages for a workspace.

When faced with deciding between these two laboratory work surfaces, solid surface countertops vs. laminate, it’s important to consider a wide variety of factors…from cost to application.

Here are the differences between the two materials and what you need to know to help you select which is best for your workspace.

What Is A Solid Surface Countertop?

Solid surface countertops are made from human-designed countertop materials. They’re non-porous and homogeneous, maintaining a consistent look, feel and durability across the top.

and homogeneous, maintaining a consistent look, feel and durability across the top.

They are composed of a combination of natural minerals (66%) with binding resins (33%). These resins come from acrylic, polyester and plastic. The mineral portion of the mixture depends on the desired final look and may include minerals like marble and granite. The mineral portion also typically includes aluminum trihydrate, which is a fine white powder that is responsible for the smooth appearance that solid surface countertops feature.

This mixture chemically cures and is heated to 140 degrees F or more to form a solid material that can be customized to a specific size and shape.

What Is A Laminate Countertop?

Laminate countertops are manufactured by compressing layers of paper and resin over top a thick glued brown Kraft paper. Manufacturers then heat the layers together, causing them to bond into a single thick layer. This layer is usually placed over a wooden substrate.

While this is a basic version of laminate countertops, there are other types of laminate countertops available in the marketplace.

For example, chemical laminate countertops are specially treated for use in laboratories. They are designed to stand up better to harsh conditions and exposure to chemicals than the more basic version.

ESD laminate surfaces are made of high-pressure laminate with a carbon layer that dissipates any static that is generated. This type of countertop is important in environments where electronic discharge is a concern. This type of service also provides other benefits, such as resistance to staining and chemicals that include acetone, gasoline and 10% ammonium solutions.

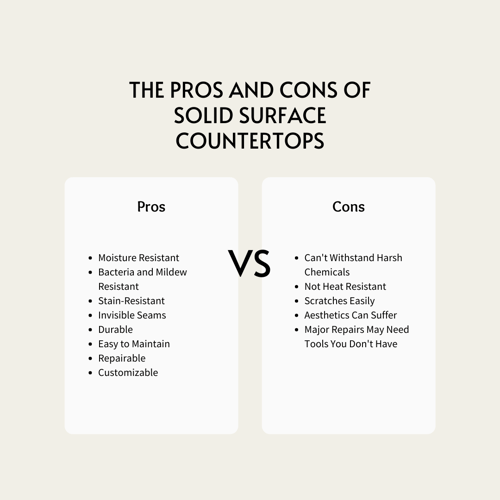

Solid Surface Countertops: Pros And Cons

Solid surface countertops have their advantages and disadvantages. Both should be weighed when determining whether solid surface material is best for your lab.

Pros

- Moisture resistant: Because solid surface countertop is non-porous, moisture doesn't seep into the tiny imperfections found in natural stone.

- Bacteria and mildew resistant: Bacteria and mildew cannot survive on a non-porous solid surface.

- Stain-resistant: The non-porous feature allows the solid surface to resist stains.

- Invisible seams: Solid surface features invisible seams, making this material a popular choice for aesthetic reasons.

- Durable: The homogeneous nature of solid surface makes it more durable than layered countertops like laminate.

- Easy to maintain: Soap and water are sufficient to keep solid surface countertops clean.

- Repairable: Should a solid surface counter suffer a nick, scratch or gouge, you can sand it out and it looks as good as new.

- Customizable: You can get them in a variety of colors and patterns that can even mimic natural stones.

Cons

- Can’t withstand harsh chemicals: Harsh chemicals can damage solid surface countertops, so labs that use chemicals on a regular basis may need to opt for a different material.

- Not heat resistant: Open flames or hot instruments can discolor and damage a solid surface countertop.

- Scratches easily: Sharp tools can scratch and damage solid surface countertops.

- Aesthetics can suffer: Solid surface tops can show scratches, which impact aesthetics, but remember, you can sand them out periodically when aesthetics matter.

- Major repairs may need tools you don't have: Major repairs may require a professional with specialized sanding and polishing tools.

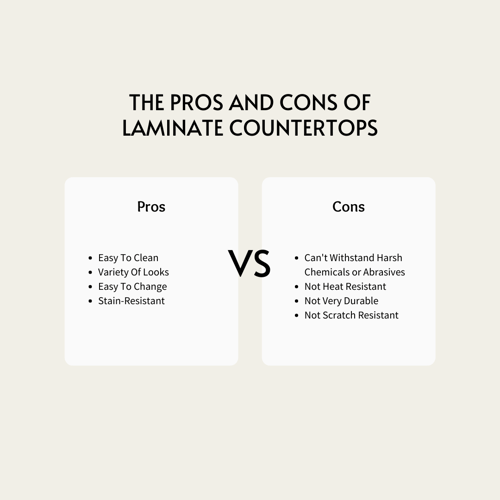

Laminate Countertops: Pros And Cons

Laminate counters have their own set of pros and cons as well that should be carefully considered before making an investment.

Pros

- Easy to clean: Laminate countertops simply need warm water and dish soap. Scrubbing with a non-abrasive brush or sponge can lift away dirt and grime.

- Variety of looks: Laminate comes in a variety of colors and patterns. Natural stone surfaces like granite and marble can be mimicked as well.

- Easy to change: If a remodel is in the future, laminate countertops are easy to swap out for another look.

- Stain-resistant: Laminate countertops are mostly stain-resistant, but don’t hold up well to stronger chemicals. In this case, you’re better off choosing a specialty laminate like chemical laminate countertops.

Cons

- Can’t withstand harsh chemicals or abrasives: Harsh chemicals can damage laminate countertops, unless you choose a special finish like what chemical laminate countertops offer.

- Not very durable: Because of how laminate is constructed in layers, it’s not as durable as solid surface.

- Not heat resistant: Most laminate countertops can only withstand heat up to around 150 degrees F.

- Not scratch resistant: Laminate countertops don’t fare well against sharp objects.

Cost Of Solid Surface Vs. Laminate

Cost often impacts any decision, but when it comes to choosing a countertop for your workspace, it can be a top consideration.

Solid surface countertops range in price between $50 and $200 per square foot. Special finishes, edging and certain pigments can drive the price up. Prices will also vary by manufacturer.

Laminate countertops are just $10 to $30 per square foot. They are one of the least expensive choices in countertop materials.

Specialty laminate countertops will have a higher price tag. Chemical laminate countertops range between $20 and $60 per square foot. With ESD laminate countertops, you can expect to pay 15% to 30% more for an ESD product over a non-ESD product.

However, there are many additional factors to consider when weighing the cost of a lab countertop, including the durability of the material. If you must frequently replace your countertop because of damage, your lifetime cost is going to be significantly higher.

Which Is Better? Solid Surface Countertops Or Laminate?

The answer to this question comes down to your specific lab’s application and your budget. While laminate costs less, if it won’t hold up against the conditions in your workspace, you could find yourself wasting money in the long run.

Solid surface countertops offer many benefits, from their invisible seams to their non-porous features that help labs meet clean room requirements. Yet this popular material isn’t right for every laboratory or workspace, especially if harsh chemicals or open flames are routinely used.

If neither of these seem like a good fit for your lab space, there are other materials that may be better investments, including phenolic resin and epoxy resin. Both are resistant to many of the harsh conditions found in labs, from chemicals to bacteria and heat exposure. Other options can be found in our article, Top 5 Materials To Consider For Your Lab Countertops.