As new businesses and industries have developed, the need for specialized manufacturing environments has become necessary. Air flow rates and direction, pressurization, temperature, humidity and specialized filtration all need to be tightly controlled.

But for companies that are starting out or in a growth phase, dedicating a conventional, fixed room for this may not be the best answer. Portable clean rooms offer a solution that many businesses are just now becoming familiar with.

What is a Portable Clean Room?

Typically used in manufacturing or scientific research, a portable clean room is a room in which airborne particles, such as dust, airborne microbes, aerosol particles, and chemical vapors are controlled to specified limits.

Typically used in manufacturing or scientific research, a portable clean room is a room in which airborne particles, such as dust, airborne microbes, aerosol particles, and chemical vapors are controlled to specified limits.

The key component in reducing particulate contamination is a High Efficiency Particulate Air (HEPA) filter that is used to trap particles that are 0.3 micron and larger in size. All of the air delivered to a clean room passes through HEPA filters, and in some cases where stringent cleanliness performance is necessary, Ultra Low Particulate Air (ULPA) filters are used.

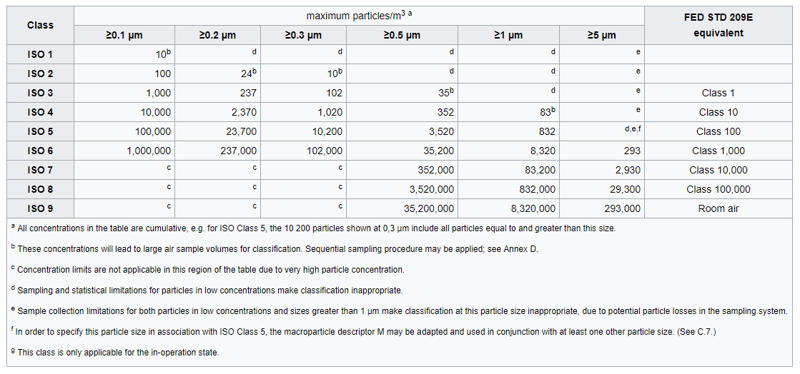

Clean rooms are classified by how clean the air is and are assigned an ISO Class. The USA cleanroom classification standards FS 209E and ISO 14644-1 require specific particle count measurements and calculations to classify the cleanliness level of a clean room or clean area.

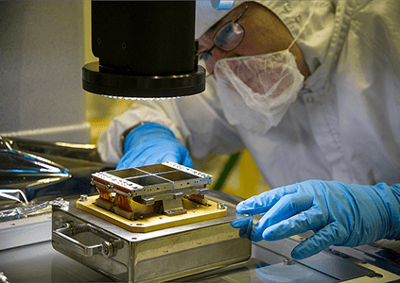

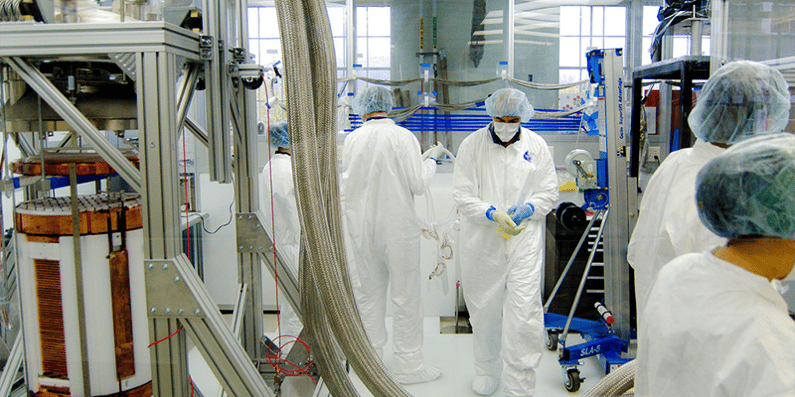

Depending on the room classification or application, facility personnel in these rooms may be required to wear cleanroom garments such as boots, shoes, aprons, beard covers, bouffant caps, coveralls, face masks, frocks/lab coats, gowns, glove and finger cots, hairnets, hoods, sleeves and shoe covers in the controlled environment.

The type of clean room garments used reflect the cleanroom and product specifications. Low-level clean rooms may only require users to put on special shoes with completely smooth soles that do not track in dust or dirt. However, shoe bottoms must not create slipping hazards since safety always takes precedence. Class 10,000 cleanrooms may use simple smocks, head covers, and booties. For Class 10 clean rooms, careful gown wearing procedures with a zipped cover all, boots, gloves and complete respirator enclosure are required.

What is a Portable Clean Room Used for?

Portable cleanrooms, also known as modular cleanrooms or softwall cleanrooms, are commonly used in a variety of applications to prevent contamination of electronic parts, medical parts and devices, medical testing samples and scientific experiments. Typical industries using portable clean rooms include semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy. They are even used in the marijuana plant growing industry in states where it is legal.

Larger companies typically retrofit existing hardwall rooms or build new ones, to meet specified standards. But for small and medium-sized businesses that are still growing, have little space or need options, portable clean rooms are often the ideal solution. And, for those companies just starting out, you can read about Why A Laminar Flow Bench May Be Just What Your Business Needs.

What are the Advantages of a Portable Clean Room?

Portable, modular clean rooms do have advantages over conventional, brick-and-mortar clean rooms due to unique, flexible capabilities.

Versatility - They can be assembled, disassembled or relocated at any time for site work. This portability is especially important as businesses grow and change.

Reconfiguration - They are comparatively inexpensive to make larger, smaller or change shapes as needs change.

Cleanliness Control - They are easy to retrofit as specifications and other user requirements change.

Cost - They offer a customized, clean environment at a fraction of the cost associated with a conventional cleanroom. An average portable clean room cost for a 10’ x 10’ space is $10,000 to $15,000, depending on the controls and specifications needed.

Lead Time - They can be delivered at a fraction of the time that it takes to order and build a conventional cleanroom.

If you think a portable clean room is a great option for your business, it is important to find the right manufacturing partner. There are additional factors to consider in the design of your space, such as clean room furniture and lab countertops, that an experienced manufacturer can help you figure out what's right for your workspace.

Product quality, customization and lead times are all important factors you should consider as well in your selection to minimize problems and hassles that go along with implementation.

Image Credit: Photo by NASA Goddard Space Flight Center | CC BY

Image Credit: Photo by luxdarkmatter | CC BY