Static electricity can be a big problem in laboratory and industrial settings, impacting production, accuracy and worker safety.

There are a number of anti-static solutions available, and one of them involves what is already found in most workspaces... furniture. Being mindful of the type and quality of furniture you include in your laboratory or industrial workspace can make a significant impact on the amount of static you generate.

And, for those who work in industrial locations, labs or warehouses, static electricity can be a far greater problem than what many managers may realize - especially if the workspace has cleanroom requirements or Electro Static Dissipative (ESD) requirements.

Below, we’ll explain what static electricity is, how it can impact your operations and how the type of furniture you choose can have an effect on how much static electricity is found in your workspace.

What Is Static Electricity?

Most of us have experienced static electricity in one form or another - either in our personal lives or in our workspace. One common cause that produces static charge buildup is when contact occurs between solid materials.

Most of us have experienced static electricity in one form or another - either in our personal lives or in our workspace. One common cause that produces static charge buildup is when contact occurs between solid materials.

Here’s how it occurs... When two objects rub together, one object gives up electrons to another object. This causes one to become more positively charged, while the other object becomes more negatively charged. This creates a charge imbalance once the two materials or objects separate.

These charges then may build up on an object’s surface until they find a way to be discharged. For the most part, static electricity can be a nuisance, but not a serious problem. In industrial workspaces and laboratories, however, static electricity can interfere with accuracy, and even be damaging or dangerous.

How Can It Impact Your Operations?

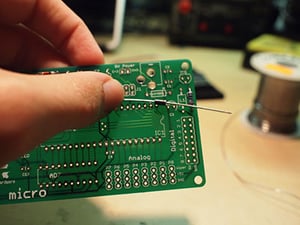

Some industries such as electronics have a long history of dealing with static electricity and have built-in protocols to combat its effects.

However, more industries, especially those that must implement cleanroom environments, are becoming concerned with the contamination that can occur from static electricity.

Precision weighing

For example, static charge can have a tremendous impact on precision weighing - something often practiced in laboratories and in manufacturing industries. That’s because static charges can attract particulates, including dust.

These particles can build up on scale components, a weighing pan or what’s being weighed itself. This type of contamination can result in weighing inaccuracies, which can be costly.

Hazards

Static charge buildup also can be dangerous. According to the Occupational Safety and Health Administration (OSHA), static charge buildup can cause electrical hazards because sudden high-voltage discharges can provide an ignition source for flammable substances. Many laboratories work with dangerous chemicals, and a simple spark could have devastating consequences.

In industry, static can be caused by machinery that generates friction, contact and separation, as well as in situations where rapid heat changes occur. Even people can build up a charge simply by walking, and when they walk by a machine, can receive a shock.

Cleanroom Specifications

If you work in a cleanroom, it’s important to ensure that the humidity is at appropriate levels, since humid air can help remove some charge. Dry environments, on the other hand, can be prone to static buildup.

Choosing ESD Materials

As mentioned above, there are a number of anti-static devices and solutions available. However, the furniture, fabrics and materials you choose for your lab or manufacturing space also can impact how static free your workstation is.

As mentioned above, there are a number of anti-static devices and solutions available. However, the furniture, fabrics and materials you choose for your lab or manufacturing space also can impact how static free your workstation is.

Not all workspaces are alike. Some have basic requirements, while others have Electro Static Dissipative (ESD) requirements. Some also have cleanroom requirements.

That’s why choosing the right furniture for your space to meet these requirements is critical.

ESD chairs, for instance, include fabrics and vinyls that are suitable for manufacturers of electronic products and those that have strict requirements in their labs. These types of chairs are manufactured with high-quality, non-flammable fabrics that are specifically designed to protect your workers from electrostatic discharge problems.

In addition to maximum ergonomic support and pneumatic height adjustments, ESD chairs include:

- Non-conductive materials

- Static-free fabric

- Static-free casters

- Urethane foam used in the seat and back

- A design that minimizes environmental pollutants in clean room applications

Countertops also can be constructed to minimize static electricity in a workspace. When choosing the material for your laboratory workstations, you’ll also want to consider the material’s resistance to substances you work with or other factors in your environment, including chemicals, heat, abrasives and moisture.

ESD Laminate work surfaces, in particular, are ideal for applications where parts and materials are sensitive to static, and need protection.

This type of work surface is made of high pressure laminate with a carbon layer for dissipation of static. Chemical resistant laminate work surfaces are similar, but have a resin coating for chemical resistance.

Bottom Line

Static electricity can be problematic - and even dangerous - in laboratory and industrial settings. The furniture you include in your space, however, can play an important role in minimizing any risks.

If your company is concerned with ESD and deals with sensitive electronic components or chemicals that can pose dangerous conditions when in contact with a static charge, incorporating furniture into your workspace that helps reduce ESD is an important step to protecting your products and workers.