As a business owner, you are always looking for new and better ways to produce quality products. You know that defective products will cost your company money, but you don’t have a ton of money to invest in your facility.

So what do you do?

If your company requires a sterile, clean work environment as part of your production process… testing, manufacturing, assembly or packaging...a laminar flow workbench may be just what you need.

What is a Laminar Flow Bench?

A laminar flow bench (LFB) is an enclosed workbench designed to prevent contamination of particle sensitive materials. In  this type of bench, air is drawn through a HEPA ( High Efficiency Particulate Air) filter and blown away from the parts or materials on the bench in a unidirectional manner, either vertically or horizontally across the worksurface. There is little to no cross-over of air streams that would move particles around; it simply moves the particles in one direction straight out of the enclosed area.

this type of bench, air is drawn through a HEPA ( High Efficiency Particulate Air) filter and blown away from the parts or materials on the bench in a unidirectional manner, either vertically or horizontally across the worksurface. There is little to no cross-over of air streams that would move particles around; it simply moves the particles in one direction straight out of the enclosed area.

Typically, an LFB will come with a Class 100 HEPA filter, which means that there should not be more than 100 particles (0.5 microns or larger) per cubic foot of air.

As a frame of reference, the ambient air outside in a typical city environment contains 35,000,000 particles per cubic meter, 0.5 mm and larger in diameter. This gives you an idea of how clean the air is moving through the work area of the enclosed bench.

When It Makes Sense to Use One

Laminar flow workbenches were designed to supplement clean rooms, which can be costly to build. Using an LFB can be a cost-effective way of expanding production for companies that aren’t ready to build a clean room or increase the size of an existing one.

Laminar flow workbenches are used in applications where clean air and a sterile work environment are necessary to prevent contamination of parts, samples or materials. Typical applications include:

Medical and Research Laboratories - These types of laboratories often require sterile environments to prevent airborne contamination of experiments and samples. In some cases, a

UV germicidal lamp is used to sterilize the interior and contents before usage to prevent contamination of experiments from bacteria, viruses and protozoa. The lamp is then turned off while the laminar flow hood is turned on to prevent the worker from being exposed to stray ultraviolet light emissions. If you fumes are produced as part of your lab process, you may need a fume hood. Learn whether a ducted or ductless fume hood is best for your business.

Medical Equipment and Implant Assembly - For obvious reasons, every piece of medical equipment and implant device or part has to be sterile. Laminar flow workbenches are used in the manufacturing, assembly and packaging processes to keep dust particles off and contamination from happening.

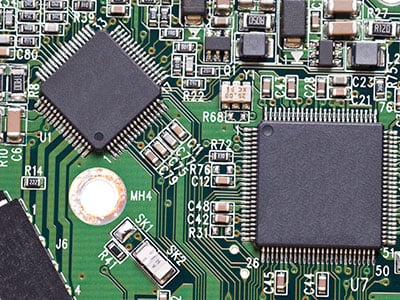

Electronic Parts Assembly and Testing - Electronic parts are very sensitive to surfaces being soiled by contaminants. These contaminants can create a defect that can “kill” a miniature circuit. Dust on the surface coating of a wafer or chip can create contact resistance and prevent a relay from working. In the electronic world, a tiny speck of dust on a microchip can be as damaging as a huge boulder and costs companies millions of dollars every year. A laminar flow bench can be used in both the assembly or testing processes.

Electronic Parts Assembly and Testing - Electronic parts are very sensitive to surfaces being soiled by contaminants. These contaminants can create a defect that can “kill” a miniature circuit. Dust on the surface coating of a wafer or chip can create contact resistance and prevent a relay from working. In the electronic world, a tiny speck of dust on a microchip can be as damaging as a huge boulder and costs companies millions of dollars every year. A laminar flow bench can be used in both the assembly or testing processes.

In recent years, the use of LFBs has spread to other specialized applications, such as:

- Pharmaceutical Production

- Food Processing

- Data Recovery

- Tissue Culture

- Stem Cell Therapy Processes

- Projection Lens Assembly

Things to Consider When Using a Laminar Flow Bench

- Laminar flow workbenches should not to be used with biohazards or other hazardous materials. These materials require a cabinet that provides both a clean environment and containment or evacuation of hazardous substances.

- If work is done above the work surface, such as adding a sample to test tubes, vertical flow is best because the air is cleanest closest to the filter or where the sample is accessed.

- For applications such as agar samples, the most critical samples should be near the filter in a horizontal flow bench so they occupy the cleanest space and hands do not pass over them.

- When using a laminar flow workbench, let it run for several minutes before introducing samples to assure that all particulate is swept out of the area.

- Check to see if your manufacturer will ship your bench knocked down or fully assembled and crated. It will cost less and may be easier to get in your building if it is knocked down.

In the years to come, as innovation continues and new industries and products are developed, more unique applications will be found for the use of laminar flow benches.